LEDs were first introduced in 1962, used originally as indicator lights. Although light output has increased significantly in recent years (especially with the introduction of 1W LEDs), basic packaging method remains largely unchanged. Industry standard still assembles one LED chip at a time: one LED die is placed in a reflective cavity, bonded to two electrical contacts, and then sealed by an epoxy or plastic lens. This approach is simple, cost effective, and adequate for most general illumination purposes.

Following the trend of replacing traditional light bulbs with LED technology, new companies have started to appear in the horticulture industry, procuring single chip LED cells often from the same usual sources.

They assemble the LEDs using similar approaches for general illumination by sparsely populating single LED chips over sheet metal, then securing them in a box to hang over plants. This "next generation" LED grow light sports mostly red and blue chips to promote photosynthesis. However, feedback from majority of growers shows that although the newer LEDs look brighter than previous generations, the depth penetration of the light is still insufficient compared with traditional bulb type grow lights.

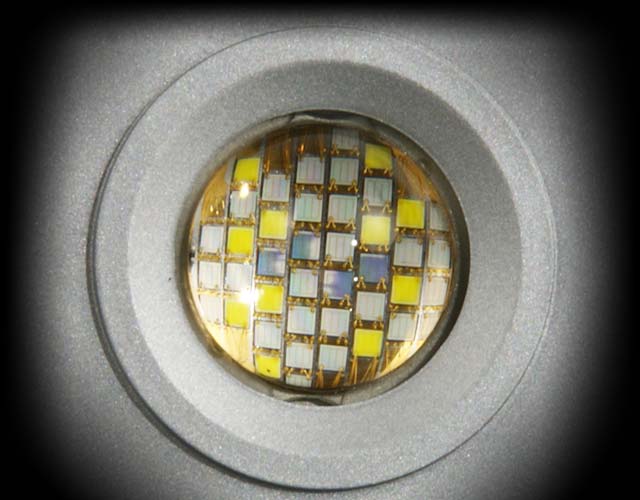

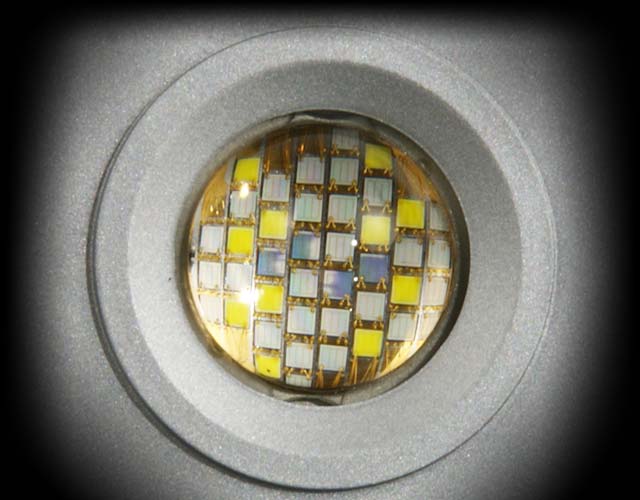

Kessil, on the other hand, takes a completely different approach. Instead of individually wrapped LED chips, Kessil applies a brand new platform that densely packs many of them together. For example, our H150 grow light uses a dense matrix platform that carries 21 LED chips in a circle smaller than a dime! This patented design is the result of over 30 million dollars in investments and five years of diligent research by DiCon. Its team of Ph.D's found a way to fundamentally resolve the thermal issue and invented a metal carrier that dissipates heat away from the core quickly. With this advanced innovation, Kessil is able to design a product that can operate at high currents and put out more light that can be effectively focused into intense beams, while still running at a device temperature much cooler than other grow lights.

Through this patented platform, we have easily conquered the two biggest challenges in designing LED fixtures, beam control and heat management, to produce a grow light that not only penetrates plants deeply, but also runs cool at higher efficiency with a longer lifetime. Kessil has assembled a team of product designers, plant biologists, and illumination engineers, all experts in their field of study, to produce a plant light that is distinctly different from everyone else's. With careful consideration of the mechanical, electrical, thermal, and optical aspects of the product, it's smaller, smarter, cooler, and brighter. Our grow light is not just the best in the class, it's in a completely separate class altogether. Kessil's own internal LED capacity allows us to make special wavelengths on our patented LED platform. We are also able to innovate quickly with our vertically integrated capabilities. The transition from design to execution is seamless. The entire flow is 100% in our control. All our findings are speedily implemented into our products. We will always be miles ahead of our competition with the best products and most advanced spectrum formulas.

You may wonder what the advantage is in having a grow light that shoots intense beams. The pictures above illustrate a simple analogy using two different nozzles mounted on the same garden hose. On the left, water sprinkles out of many tiny pores from the sunflower-type nozzle. In contrast, the picture on the right shows a single jet of water from an industrial pistol nozzle. The sprayer on the left merely mists the surface of the plants while the steady stream on the right cuts straight down to the soil. Although the amount of water is the same for both hose heads, the nozzle from the right picture is drastically more effective in reaching plant roots.

Let's apply the garden hose example to understand how DiCon's LEDs can produce much better results. Imagine the water as light. The typical LED light has tiny chips spread over a wide area similar to the individual holes that water trickles through on the left picture with the sunflower nozzle, and puts out equally weak light. Conversely, DiCon's light has many LED chips densely grouped together to send out an intense beam that behaves like the jet stream shooting out of the pistol nozzle in the right picture. Instead of sprinkling misty light onto the plant's surface layer, Kessil is able to inject light straight down to allow photosynthesis to also happen in the plant's lower tiers.

The above pictures present a clear demonstration of how Kessil is radically changing the way grow lights are used. On the left is the traditional approach of sparsely placing LEDs to cover the entire ceiling (image source: NASA). Conversely, the picture on the right features a single Kessil source: a compact, intense, singular source effectively projecting light deep into the plants.